| PDM Studio was developed in 2014 as a successor to a product data

management solution that had been in use since 2001. As a result, PDM

Studio combines years of practical experience with the latest

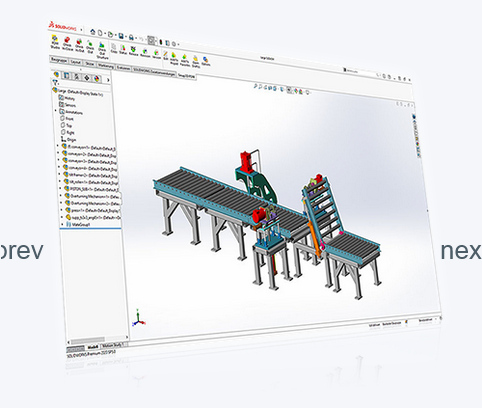

technologies and features. Our expert user support provides comprehensive technical guidance in development, software implementation, training, and ongoing support. | Founded in 1989, CAD Partner GmbH has steadily established itself as a competent software development house in mechanical and plant engineering. Our team's extensive experience ensures comprehensive, needs-based support through professional consulting and sales - from standard solutions to customized CAD and PDM complete solutions. |

Multi CADPDM Studio is designed for

maximum interoperability with other applications. It supports

established MCAD and ECAD solutions as well as selected other software

systems.

The functionality of PDM Studio can be used directly from the other application. The CAD integrations are characterised in that the inner structure of fairly complex file relationships is analysed, recorded and made available to the user by PDM Studio. All features are thus immediately available. |  |

Where-used listFind out whether and where a component is used. This allows you to estimate what effect a change will have and to decide whether you can continue to develop the component in a compatible fashion or whether the modified component should be further kept on file under a new number. This feature has a great optimization potential. Easily integrate the existing libraries or create the new ones with little effort. Use the classification tools of PDM Studio and quickly access standard parts via a list of characteristics. | |

| |

Smart project managementDocuments used in several projects often produce redundant data. PDM Studio prevents this by providing a project and folder structure that can be used for repeated storage of documents, even though this is the same document. This combines the filing structure learned by many users with the clarity of a document. | |

| |

Version and revision historyPDM Studio documents all past document states. Earlier versions can be accessed at any time, including their life cycle phase and any existing comments. For example, it is possible to quickly and conveniently determine the condition in which a component was installed at a particular point in time. The mapping of comprehensible and consistent revision history is particularly important for professional quality management. PDM Studio provides wizards for this purpose and enables selective revision even within complex structures. | |

| |

Web accessWeb access is the fastest and easiest way to share the PDM Studio data with others via an Internet browser, regardless of location. All search options via various parameters such as part number, file name, description, status, etc., are available. A structure and preview of the search results are included. | |

| |

Export/Import - Mass Data ProcessingThe so-called PartKeeper can be used to export filter results for certain documents to Excel. Their metadata can be conveniently edited and supplemented there. By re-importing the information, even bulk data is quickly and easily updated in PDM Studio via batch processing. PartKeeper is also available as a separate tool if mass data is to be optimised before it is imported into PDM Studio for the first time. | |

| |

LanguagesPDM Studio is available in German, English, and Chinese. Additional languages can be easily added using translation tables. This means that PDM Studio can be quickly and easily adapted to local conditions and user acceptance increases considerably. |

| |

| |

| |

| |

|