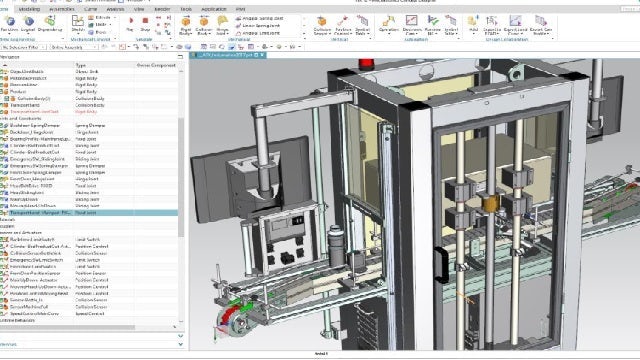

NX CAD software interoperability

NX

CAD software is highly regarded for its robust interoperability the

ability to work seamlessly with different software, systems and data

formats. This feature is crucial in today's multidisciplinary,

collaborative and increasingly digital product development environments.

Leveraging

NX CAD software provides significant benefits such as seamless data

exchange, integration with other software & platforms and

cross-disciplinary & global collaboration. It supports a wide range

of file formats and standards, integrates with PLM, CAM, CAE and IoT

systems and offers extensive customization and automation capabilities.

With NX CAD, you can maintain flexibility, optimize workflows and

enhance collaboration across your complex product development

environments.

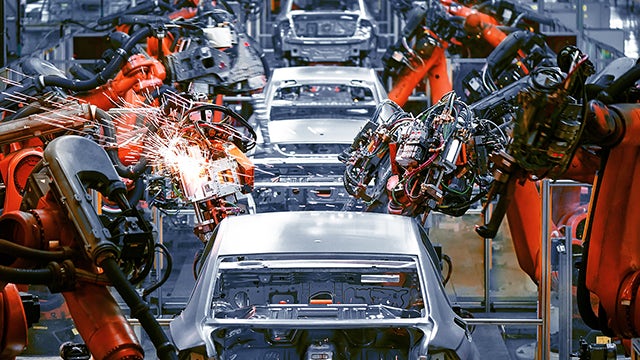

Advantages of computer-aided design (CAD)

Computer-aided

design (CAD) software offers numerous advantages across various fields

such as engineering, architecture, product design and manufacturing.

With digital tools for creating, modifying, analyzing and optimizing

designs, leveraging CAD software enhances your efficiency, accuracy,

collaboration and innovation.

With CAD software, you can

experience advantages ranging from improved accuracy, enhanced

collaboration and better visualization to increased creativity and

scalability, cost and time savings and reduced rework. CAD software

helps you achieve higher quality, consistency and efficiency in your

design processes, making it an indispensable tool in modern engineering,

architecture and manufacturing environments.

CAD/PLM software integration

You

can integrate NX CAD with product lifecycle management (PLM) software,

and NX comes out-of-the-box with tools to fully integrate with Siemens

Teamcenter software, one of the most powerful and widely used PLM

solutions. This integration creates a unified environment that

streamlines the entire product development process, from initial design

through manufacturing and beyond. Integrating CAD software with PLM

software offers substantial benefits including centralized data

management, improved collaboration, streamlined workflows, enhanced

product quality, efficient change management and reduced time-to-market.

With this integration, you can optimize your product development

processes, reduce errors, lower costs and drive innovation, making it an

invaluable solution for complex and competitive industries.

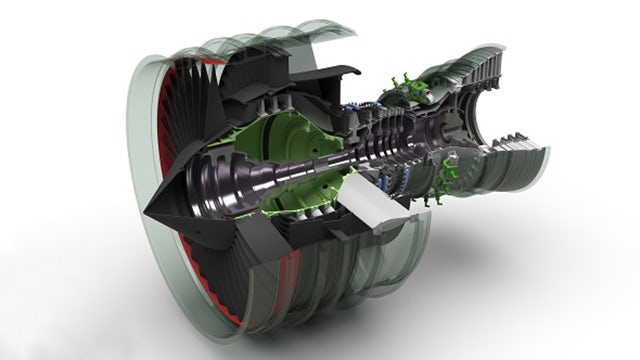

Digital twin and CAD

Leverage

NX CAD to create, manage and leverage the most comprehensive digital

twin across the entire product lifecycle. A digital twin is a virtual

representation of a physical product, process or system that enables

simulation, analysis and optimization in a virtual environment.

NX

CAD data seamlessly integrates with other tools in the Siemens

Xcelerator portfolio, such as Teamcenter (PLM), Simcenter (simulation

and testing), Insights Hub (Industrial IoT), and Opcenter (manufacturing

execution system). This integration and interoperability enables

companies to develop, simulate, validate and optimize digital twins

effectively, making NX CAD a leading platform for those looking to

leverage digital twin technology for smarter, more efficient and more

innovative product development and manufacturing.