Designed with Solid Edge users in mind, Solid Edge CAM features a rich set of tools to help you finish the job right the first time. Solid Edge CAM is a modular, flexible configuration of numerical control (NC) programming solutions that allow you to maximize the value of your machine tool investments. Easy to deploy and easy to learn, Solid Edge CAM provides powerful NC programming with a low total cost of ownership.

Ease-of-use

An intuitive, modern user interface (UI), easy-to-follow tutorials, built-in templates, and wizard guides make Solid Edge CAM remarkably easy to use. Consistent navigators manage key elements while dialogs provide graphical help and instant feedback in the graphics area.

CAD neutral capability

Understand influence of changes in the geometry or boundary conditions on the results by comparing a wide range of project variants. Assess results by numerical values, graphs or animations.

Postprocessor library

Included with Solid Edge CAM Pro, the Post Hub library enables a streamlined process to generate production-ready CNC programs for your applications. The searchable, online database lets you access more than 1,200 postprocessors directly from Solid Edge and download them to your workstation.

Tight integration with Solid Edge

Sending files from Solid Edge to Solid Edge CAM Pro is a one-button click. Send a single file or a whole manufacturing assembly. Data retains associativity, so that when late-stage design changes occur, they can be easily incorporated into the manufacturing plan.

PMI functionality

Product manufacturing information (PMI) is transferred along with geometry data from Solid Edge to Solid Edge CAM Pro. That makes it easy for the NC Programmer to design the manufacturing plan according to the engineer specifications.

Solid Edge CAM Pro provides you with the right tools to manufacture today's products.

Solid Edge CAM Pro provides comprehensive solutions for machine tool programming, from simple NC programming to high-speed and multi-axis machining, enabling you to address all types of CNC machining requirements.

Solid Edge CAM Pro offers advanced machining capabilities such as adaptive and feature based machining, smart pencil milling, and enhanced roughing routines. Toolpaths are associative to the Solid Edge parts and assemblies so the toolpaths can be quickly updated to incorporate any design changes.

Capabilities

Solid Edge CAM Pro provides supporting CNC machining and milling functions, including translators, assembly modeling, model editing, visualization, verification, post processing and shop documentation.

TurningFull range of turning tool paths, including teach-mode and other manual methods for fine control. | 2.5 Axis MillingRoughing, re-roughing, facing, z-level finishing, and hole-making methods including manual positioning and feature based automation. | 3 Axis MillingExtensive, high-speed capable, fixed axis cutting capabilities for complex surfaces, including raster, offset, adaptive clearance tool paths, and interpolated patterns, with steep/non-steep recognition, valley rest milling, and facet machining. |

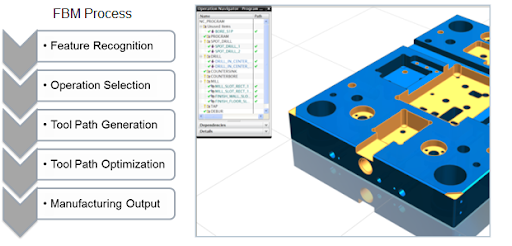

5 Axis MillingExtensive capabilities for simultaneous multi-axis cutting of complex surfaces, including both automatic and manual methods, multiple drive options and a wide variety of tool axis control. | Machine SimulationA complete kinematic machine environment for visualizing complex motion, including g-code level simulation of collision checking and multi-channel synchronization for the most accurate results. | Feature-Based MachiningCapabilities to create and modify rules-driven automation processes and feature geometry definitions in the Machining Knowledge Editor. Feature based machining allows the built-in feature recognition engine to analyze prismatic shapes and quickly create NC strategies to machine those shapes–all automatically. |

In addition to the 2.5-axis milling capabilities included with Solid Edge Classic, Foundation, and Premium active maintenance contracts, CAM Pro is available in 2.5-axis, 3-axis, and 5-axis bundles. These configurations along with numerous add-on functionalities allow users to customize the right-sized solution to best meet their individual manufacturing needs.

Solid Edge CAM Pro is designed to be used independently of any specific CAD system. It has key industry translators for data import.

Solid Edge CAM Pro is also available for integrated use with Solid Edge.

Solid Edge manufacturing solutions provide fast and easy feature-based machining, allowing you to automatically determine the machining process for a wide range of features.

Feature based machining in Solid Edge CAM Pro uses a knowledge engine to identify and create NC machining strategies for prismatic features.Unlike other CAM systems, Solid Edge CAM Pro can be used as a complete machining kit, or as a companion for other types of machining. Additionally, the operations created are true machining operations that can be modified as needed by NC programmers.

With easy tool path generation single, batch mode, or in the background CAM operations are quickly updated to match new requirements.

Capabilities

Solid Edge CAM Pro provides powerful NC programming and feature-based machining capabilities that are easy to deploy and learn.

Feature recognitionRobust feature recognition capability finds features in the topology of any model, including imported data. | Knowledge basePowerful knowledge editor applies template processes building blocks to machine a wide range of features. | 2.5 axis millingFeature-based machining functions automate the identification and programming of slots and faces. |

DrillingFeature-based machining functions automate hole making. | Feature-based Machining AuthorProvides capabilities to create and modify rules-driven automation processes and feature geometry definitions. | CAD NeutralSolid Edge CAM Pro is designed to be used independently of any specific CAD system. It has key industry translators for data import. |

Solid Edge CAM Pro provides a complete solution for CNC turning, including multi-turret and multi-spindle turning centers.

The tool supports a full range of turning tool paths, including teach-mode and other manual methods for fine control. Also available are outside and inside diameter programming for turning centers and vertical turret lathes. Face, turn, bore and groove operations are supported for roughing and finishing cuts.

Solid Edge CAM Pro allows you to cut efficiently with turning operations that tracks cut and uncut material. Configure left- or right-handed tools and specify the holder and insert as part of a tool assembly.