NX for manufacturing NX X Manufacturing StandardAutomate

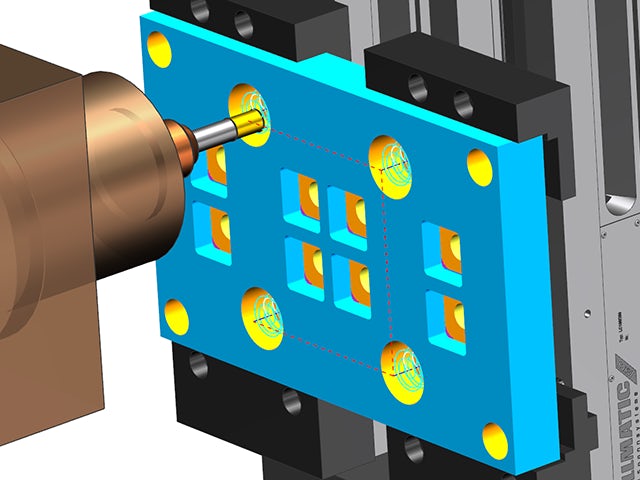

prismatic part programming using CAD/CAM, featuring 2.5-axis milling,

hole making, turning, & on-machine probing capabilities and

seamlessly integrated with industry-leading CAD tools. powered by cloud

technologies. |

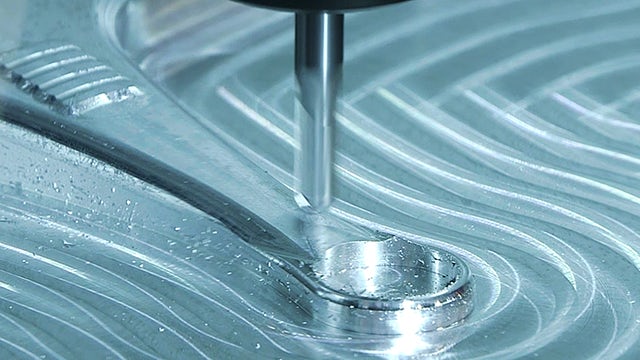

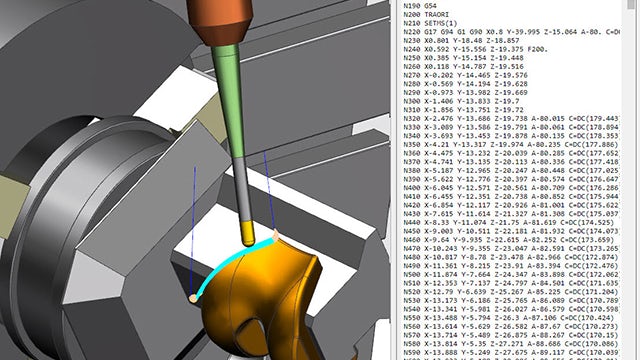

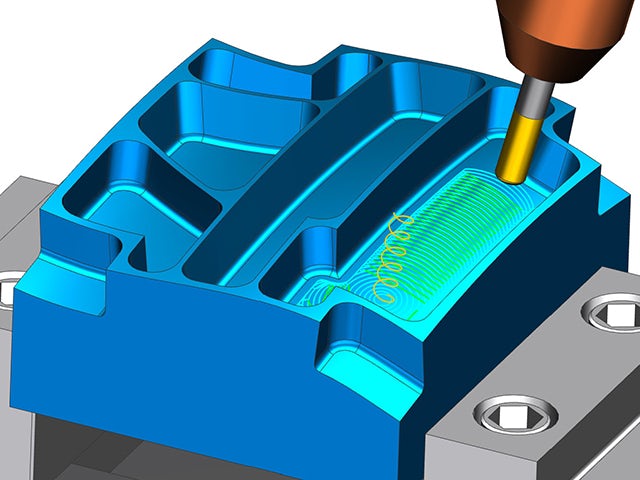

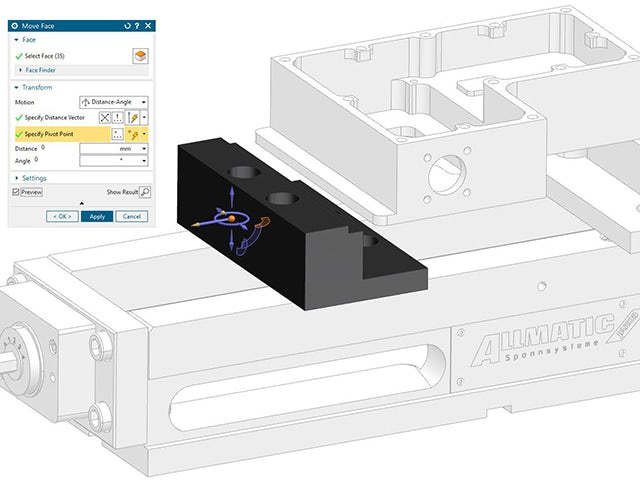

NX for manufacturing NX X Manufacturing AdvancedUse

advanced 3- and 2.5-axis milling, turning, on-machine probing

capabilities among other advanced functionalities. Leverage integrated

CAD/CAM tools streamline the preparation & programming of the most

demanding freeform parts. |

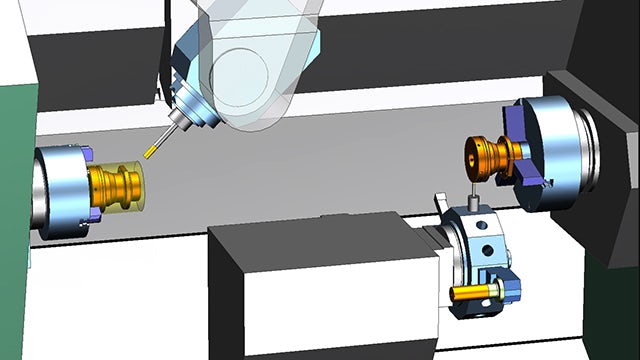

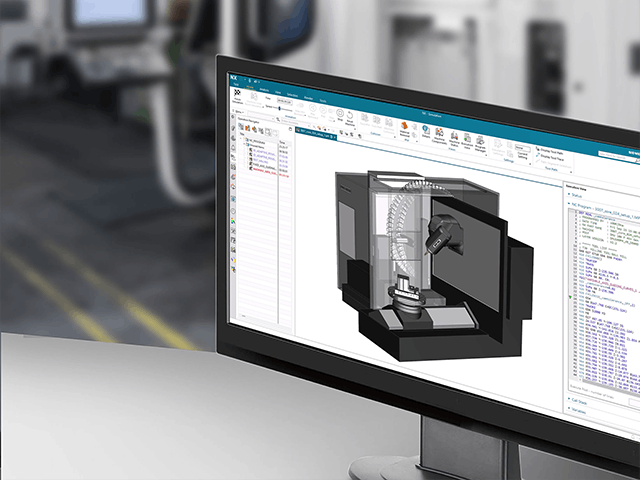

NX for manufacturing NX X Manufacturing PremiumUse

5-axis milling, rotary machining, advanced 3- & 2.5-axis milling,

turning, on-machine probing capabilities among other advanced

functionalities. Optimize complex part machining using powerful

multi-axis machining strategies. |

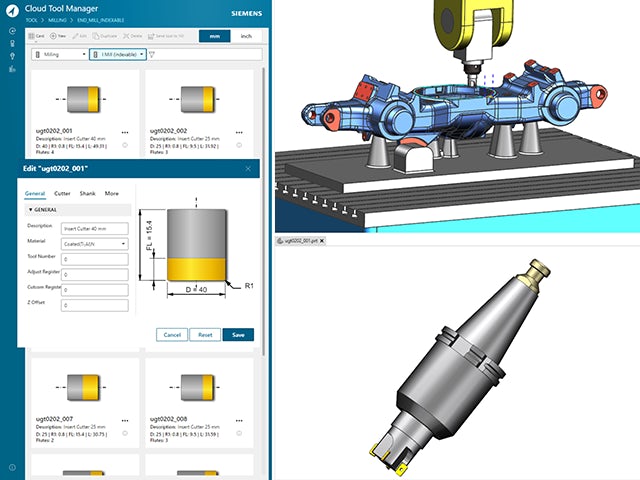

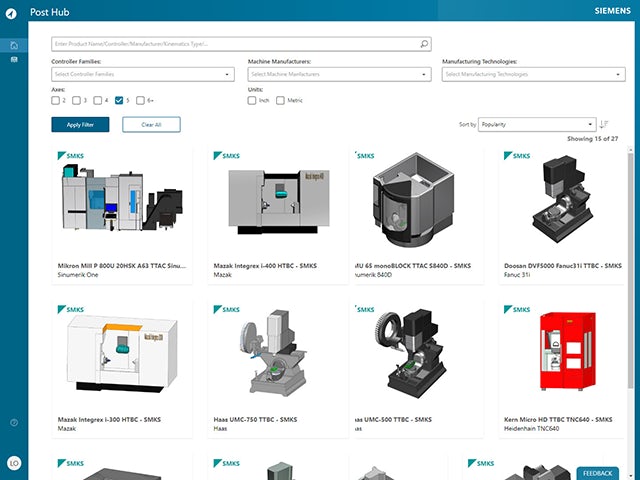

NX for manufacturing NX X Manufacturing Value Based LicensingNX

X Manufacturing add-ons are delivered exclusively using our innovative

Value Based Licensing model, providing a cost-effective solution. Expand

the capabilities of your NX X Manufacturing solution with powerful

add-ons. |

NX AM Fixed-PlaneNX

AM Fixed-Plane provides build tray setup, basic support geometry

(block, line and point) creation, and the build processor framework,

which supports build processors for a wide variety of additive

manufacturing (AM) equipment. |

NX AM Multi-AxisProvides

an interface to multi-axis and hybrid additive machines. This includes

important functions, such as model decomposition and 3D path generation.

|